- info@tasmayenterprises.com

- +91 7977178119

Water Cooled Cables are specially designed high-current flexible conductors that use a water circulation system to actively remove heat from the cable during operation. These cables are essential in high-temperature, high-load industrial environments—particularly in induction furnaces, arc furnaces, and electrolytic plants—where natural air cooling is insufficient to maintain safe operating temperatures.

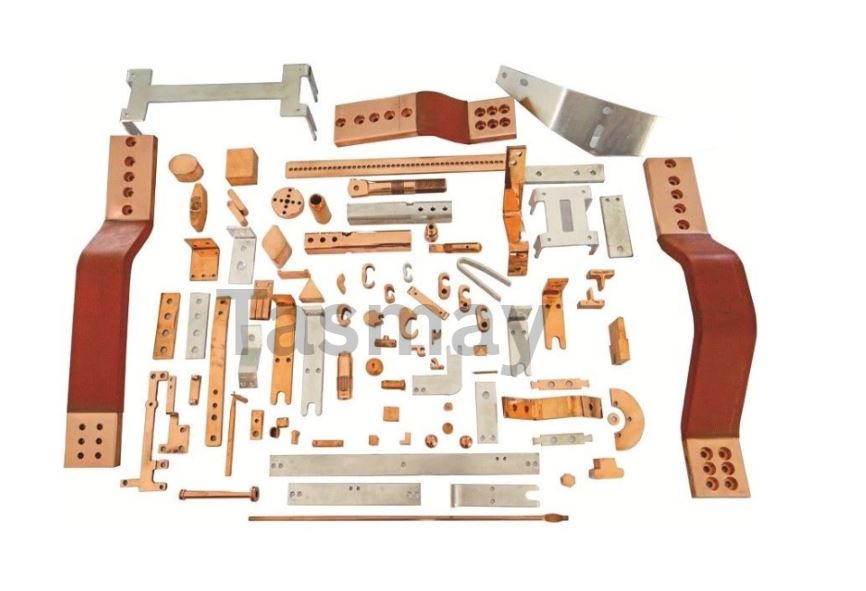

Conductor: High-conductivity, stranded or braided electrolytic copper

Inner Hose: Durable rubber or silicone tube allowing water flow through the center

Outer Jacket: Reinforced heat-resistant rubber, silicone, or fiberglass braid, providing insulation and protection

Terminals: Copper lugs or customized water-cooled connectors (often flanged) at both ends

Water Ports: Inlet and outlet fittings for coolant connection

💧 Active Cooling via Internal Water Flow

🔥 Handles Extremely High Currents

🌡️ Controls Thermal Expansion & Heat Build-Up

⚙️ Flexible for Moving Connections

🧱 Protected Against Mechanical and Electrical Stress

As electrical current flows through the cable, it generates heat. In water-cooled cables, coolant water is circulated through an internal channel, effectively absorbing and carrying away this heat, which helps:

Maintain conductor performance

Protect surrounding components

Extend the life of the cable

Induction Melting & Heating Furnaces

Electric Arc Furnaces (EAF)

Resistance Welding Equipment

Electrolysis and Electroplating Systems

Heavy Industrial Machinery in Steel, Glass, and Mining Sectors

✅ Superior Heat Dissipation for High-Load Systems

✅ Extended Cable Life in Harsh Environments

✅ Minimizes Thermal Degradation of Conductors

✅ Supports Continuous Duty Applications

✅ Customizable Lengths, Hose Sizes, and Connectors

| Feature | Water Cooled Cables | Air Cooled Cables |

|---|---|---|

| Cooling Method | Internal water circulation | Ambient air convection |

| Current Capacity | Very High | High |

| Space Requirement | Compact (no air gap needed) | Requires airflow clearance |

| Maintenance | Requires water system upkeep | Minimal |

| Best Use | High heat, continuous loads | Moderate loads, ventilated areas |

Ensure clean, non-corrosive water supply to prevent scaling or blockages

Regularly inspect for leakage or hose wear

Monitor water flow and pressure for optimal cooling efficiency

Water Cooled Cables are critical components for high-power electrical systems operating under extreme thermal loads. Their ability to maintain low conductor temperatures during intense operation makes them indispensable for industrial heat-processing equipment and electrometallurgical systems. With proper installation and maintenance, they deliver safe, efficient, and long-lasting performance.

Need technical guidance or custom sizing?

Contact us today to discuss your requirements. Our team will assist you with technical details, price quotes, and delivery timelines.

Copyright © 2025. All Rights Reserved. Design and Concept by Tasmay Enterprises.